Should have said "with driveshafts removed" I was changing over series 2 suspension to series one at the time..............................

Tim

Rubber supports under the front spring

-

Huib

Re: Follow-up

I used various methods as described above. They are basically dangerous. Everytime it goes well, it becomes more dangerous as you will be a little bit more careless. At least this is how I work. When after the umptiest time a Fulvia decided to fall over me I designed the tools as shown below. Fortunately I could jump away just in time. I discarded any hydraulic solutions as hydraulic jacks are also unsafe. They leak and if a seal suddenly gives away it collapses.

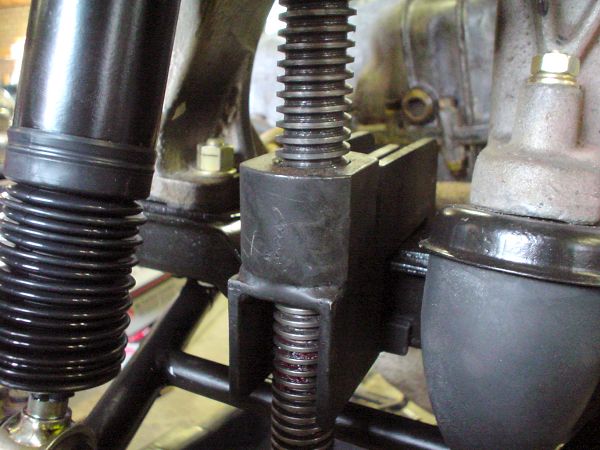

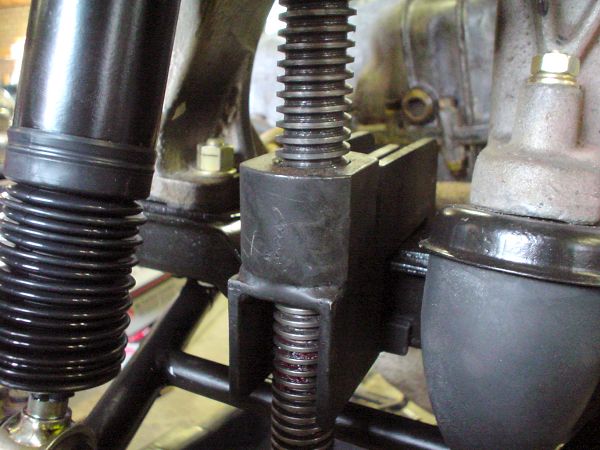

My tools consist of a hook which I clamped around the subframe, a long trapezium thread as used in vices and a "head" on top of the trapezium thread. It uses 26 mm thread which is strong anough to also handle the 11 leaf Flavia prings.

My tools consist of a hook which I clamped around the subframe, a long trapezium thread as used in vices and a "head" on top of the trapezium thread. It uses 26 mm thread which is strong anough to also handle the 11 leaf Flavia prings.

-

tim

Re: Follow-up

Must br nice to have the resources to knock up these tools. Do you hire them out or make to order - I guess the latter would require a large grant from the European Bank of Reconstruction.

PS I also have learnt the hard way of getting careless and having a Sport topple off it axle stands with one going straight throung the fuel tank - lucky I jumped out of the way and killed all the electrics before a big bonfire. Cost 500 euros to sort and an investment in serious axel stands!

PS I also have learnt the hard way of getting careless and having a Sport topple off it axle stands with one going straight throung the fuel tank - lucky I jumped out of the way and killed all the electrics before a big bonfire. Cost 500 euros to sort and an investment in serious axel stands!

-

Huib

Re: Follow-up

I had a set made some years ago. Costed money. It has to be done by someone capable of machining and TIG welding 5 mm thick steel.

They cannot be hired out. I need the set in my workshop at all times. We never know what customer is coming in. The tools are used for small jobs as changing suspension ball joints or for more complex jobs like changing front springs.

They are quick and efficient. A 1/2" socket is welded to the bottom. One can use an air tool to jack them up without effort in a few seconds. They are reliable enough to work on the suspension without extra support unlike any hydaulic tool.

I suppose I could have some extra sets made. A very very rough cost estimate is 200 euro per set.

They cannot be hired out. I need the set in my workshop at all times. We never know what customer is coming in. The tools are used for small jobs as changing suspension ball joints or for more complex jobs like changing front springs.

They are quick and efficient. A 1/2" socket is welded to the bottom. One can use an air tool to jack them up without effort in a few seconds. They are reliable enough to work on the suspension without extra support unlike any hydaulic tool.

I suppose I could have some extra sets made. A very very rough cost estimate is 200 euro per set.